This time of year you want to be extra kind to your sewing machine technicians. Here are a few things that FREAK sewing machine service people out and a few hints on how to stay on their good side.

Check Your Sewing Machine in For Service With a 15¢ Spool of Thread On It

When I saw this today, I immediately sat down to write this blog. All of us get the heebie-jeebies when we see an old thread on a sewing machine. This thread is so old it belongs in a museum. No wonder the machine doesn’t sew well!

TIP:

Remove all thread from the machine prior to dropping it off for service.

PSA: Wood spools are collector’s items these days. Put all your wooden spools in a pretty jar for display. Please do not use them in a sewing machine.

Sew With Glitter

‘Tis the season for extra glittery fabrics. If you have ever been around little girls, you know glitter happens. When you choose to sew with glittery fabrics keep in mind how hard glitter is to clean off of normal surfaces. Now imagine trying to get it out of the bobbin area.

Tip:

If sewing with glitter, take the time to remove as much of it as possible BEFORE bringing the machine in for service. Trust me!

Use Canned Air

Canned air is NOT good for sewing machines. It blows more lint into the back of the machine and into all those moving parts, electronics and motors. This is no place for lint. As soon as a machine is opened up, they can tell if you use canned air or not.

Tell Them You Have Never Had Your Machine Serviced

This is not something to brag about to your friendly sewing machine technician. If you truly have not had it serviced in a long time, they will forgive you.

Tip:

Don’t make a big deal about how long it actually has been since your last confession, I mean, sewing machine service.

Sharpen Your Own Sewing Machine Needles

This is NOT a thing! Sharpening your own sewing machine needles is the worst idea ever. We found a needle in a machine that was much shorter than we were used to seeing. After careful inspection, we realized the owner had tried sharpening the needle.

Tip:

Always have plenty of NEW needles on hand.

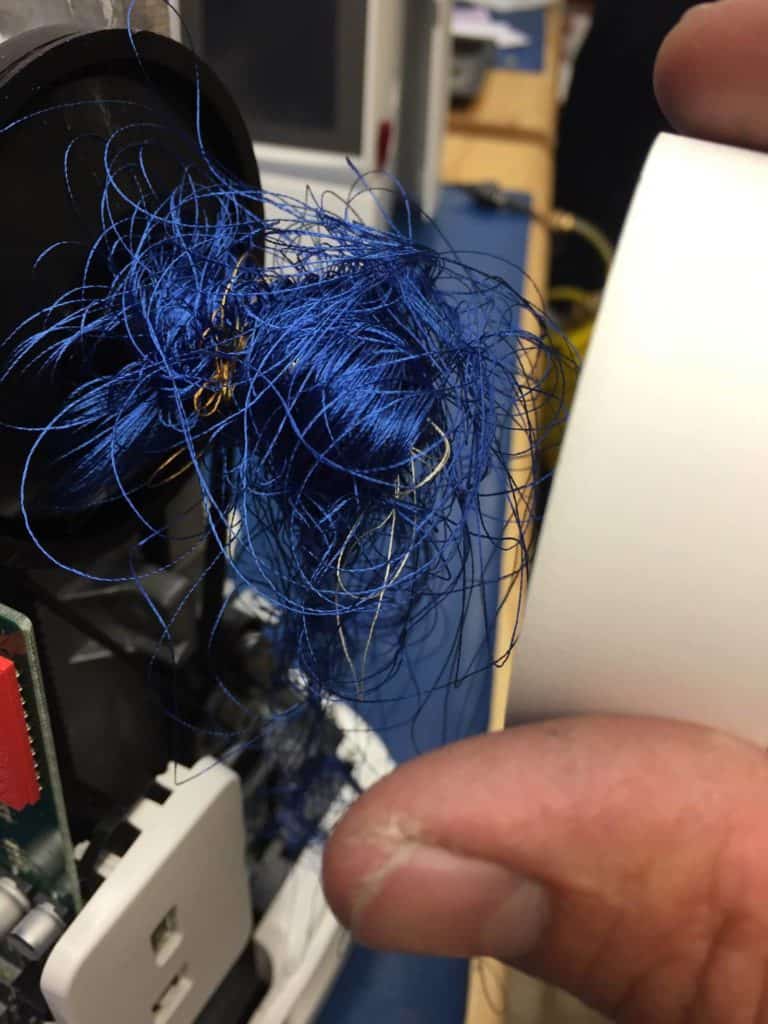

Thread Caught in the Hand Wheel

When the unattended thread is left hanging around, it is guaranteed to get wrapped around the hand wheel of the machine. Please read the following blog to learn more about this problem, how to avoid it, and see amazing other pictures of places we have found the thread.

Rust in the Sewing Machine

When sewing machines get wet or are stored in damp environments they can rust. Rust is never good and can give sewing machine mechanics an instant headache.

Tip:

Keep sewing machines in comfortable environments to help keep them from getting rusty.

In Conclusion…

Stay on the nice list at your local sewing machine repair store by following these helpful tips prior to your next sewing machine service.

Tip:

If you ever feel you need to ask for a little forgiveness, bring cookies!

If you are a service person, tell us in the comments below what else freaks you out. Or if you have had a unique sewing machine service situation that happened to you, please share it below.