Are you an embroidery enthusiast who has experienced the frustration of unexpected embroidery tension issues while working on a project? Whether you are a seasoned embroiderer or a newbie just starting to explore the creative world of embroidery, understanding common problems and knowing how to troubleshoot them is essential for maintaining a smooth stitching experience.

In a recent embroidery mishap shared in the Sewing Mastery online course community, a fellow embroiderer faced a sudden thread tension issue that marred their otherwise perfect stitching. The abrupt transition from flawless embroidery to a puzzling problem is a scenario that many of us can relate to. Let’s delve into some valuable tips and tricks shared in the video tutorial to help you overcome similar challenges and keep your embroidery projects on track.

One of the first steps in troubleshooting embroidery tension issues is to check the fundamentals. Ensure that your needle is in good condition and correctly inserted and that your fabric is securely hooped to prevent any shifting during the embroidery process. Additionally, cleaning out any lint or debris from the bobbin area and underneath the throat plate can help maintain smooth stitching performance.

If you encounter embroidery tension issues that result in bobbin thread appearing on the top of your fabric, here are some practical solutions to consider:

- Rethread Your Machine: Sometimes, simply rethreading your embroidery machine can resolve tension problems. Make sure to follow the threading path correctly and ensure that the thread is properly seated in the tension discs.

- Clean the Tension Discs: Use a paper towel dampened with a gentle cleaner, such as Windex, to clean the tension discs in your machine. This can remove any accumulated lint or debris that may be affecting the tension.

- Check the Bobbin: Ensure that the bobbin is properly inserted and that the thread is correctly threaded through the bobbin tension. For drop-in bobbin systems, confirm that the thread is positioned correctly for optimal tension.

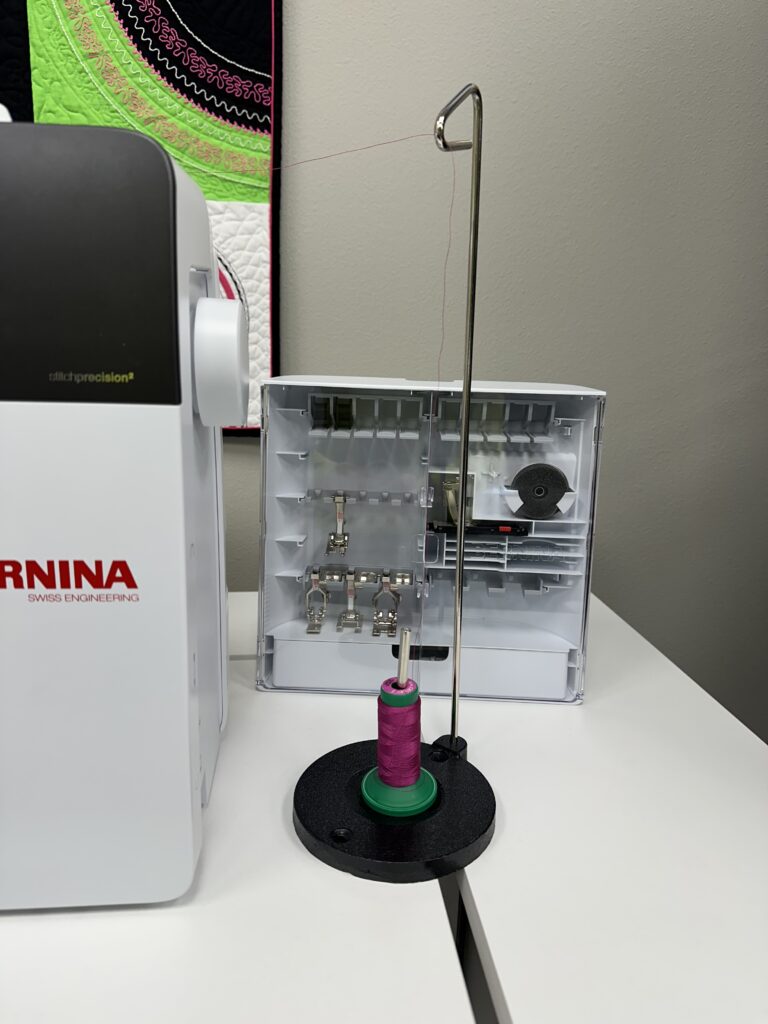

- Use a Thread Stand: Consider using a thread stand to prevent thread tension issues caused by the thread getting caught between the spool and the cap. A thread stand can provide consistent thread tension and prevent disruptions during embroidery.

By understanding the root causes of common embroidery tension problems and implementing the suggested solutions, you can enhance your embroidery experience and achieve professional-looking results with ease. Remember, quality embroidery thread, regular maintenance of your machine, and attention to thread tension play key roles in ensuring successful embroidery outcomes.

If you’re looking to deepen your embroidery skills and master the art of machine embroidery, consider enrolling in our MOST POPULAR Embroidery Essentials online course. From mastering the essentials of embroidery to refining your stitching techniques, our courses are designed to help you unlock your creativity and tackle any embroidery project with confidence.

Whether you’re troubleshooting a pesky thread tension issue or seeking guidance on choosing the right courses for your skill level, our team at Sewing Mastery is here to support you every step of the way. Feel free to reach out to us at [email protected] with your machine details, and we’ll curate personalized recommendations to elevate your embroidery journey.

Join us as we embark on a transformative embroidery experience, filled with insights, tips, and techniques to enhance your stitching prowess. Together, let’s unravel the mysteries of embroidery and stitch our way to success!