My mom has sewed for a living all my life. I remember hanging out on the floor playing at a very young age while she sewed. The gentle hum of a sewing machine in the background has always been part of our family.

Ahhhh, the gentle hum.

Her machine never sounded like a thrashing machine. She always took care of her most precious tools, her sewing machine, and serger. Just the other day she mentioned her 20+-year-old serger was still running like a top! I could not believe it. But, when you take care of your sewing machines, sergers, and embroidery machines as recommended, they are guaranteed to return the favor.

All sewing machines, sergers, and embroidery machines need basic lint removal every 2-3 bobbins. Fabrics are linty, some threads are linty, and that all leads to moving parts moving not so freely. If you sew, you must clean out your sewing machine. Uncleaned machines lead directly to skipped stitches, uneven stitches, and broken threads right in the middle of a seam. The simple act of removing the lint from under the throat plate is the first step to a healthy and happy sewing machine.

What About Oiling?

Some machines require oil and some do not. Check the manual to see if your sewing machine needs oil. If your machine needs oiling, oil it each time lint is removed.

When Should a Sewing Machine be Professionally Serviced?

Once a year.

There are many moving parts in a sewing machine. If it moves, it needs lubrication. These days many of the moving parts are housed with computer circuit boards and wires around them. Sewing machine technicians are specially trained to maintain and service computerized sewing machines.

As a sewing machine is used, eventually the lubrication dries out. Once it has dried out, moving parts don’t work so well. The well-being of the sewing machine starts to wear out faster than if it was maintained on a regular basis.

What is Involved in Properly Servicing a Sewing Machine?

Below is a checklist of every part of the machine that is checked.

First, machines are placed on anti-static mats and the service person attaches themselves to the mat with an anti-static wrist strap. This prevents any electrostatic discharge by safely grounding themselves while working on electronic sewing machines.

Remove all covers to get to all major components.

Clean out all lint, dust, and old oil.

Look for and remove threads from the take-up lever and the hand wheel.

Check top tension disks and remove lint build-up from low-quality threads.

Check timing belt/motor belt for belt tightness. Look for any excess wear spots.

For older machines: check motor brushes and make sure the motor is turning freely.

Check all shafts for any play or wobble.

Check the wear of all barrings.

Check the mechanism that drives the feed dogs for any play.

Check all gears that drive the machine.

Check the mechanism that drives the hook in the bobbin case area.

Check for any excess play between the hook and the hook driver.

Tighten any gears that are getting loose or wobbly.

Check the bobbin winder.

Check feed dog height. A slight change in height can affect the way fabric is pulled through the machine.

Check feed dog alignment checking to make sure the feed dogs are straight and not rubbing on the stitch plate.

Oil every moving part of the machine.

Check that the needle is centering in the needle plate both from side to side and from front to back. The slightest bit off in any of the four directions can cause extra needle breakage when sewing extra wide stitches or heavy fabrics.

Check needle and hook timing.

Check that the presser foot sits straight on the feed dogs and is at the proper height.

Time the feed dog movement to the machine needle.

Calibrate bobbin case tension.

Check and clean the bobbin in case of any excess build-up of lint.

Check foot control’s electronic contacts, cord, and cord end and look for any cuts in the cord.

Test Sew Out – Once all areas of the machine have been completely checked, oiled, and adjusted. It’s time to see how it sews. The technicians are looking for a smooth running sound, balanced tension, even needle swing, centered needle position, and proper feed dog movement/balance of stitches that stitch forward and reverse. They also test sew at full sewing speed. If even the smallest area is off, it will be magnified when sewing at full speed. They use a high-quality polyester thread and also insert a new Universal size 80/12 needle.

Sergers: Sergers receive extra care as the technicians check looper timing both for the upper and lower loopers, feed dogs, and cutting knife and needles. Sergers must have precision clearance or else it will not work!

Embroidery Machines: Embroidery units require special checking of all sensors, belt tension, and arm movement. They are cleaned of any lint and oiled. When sewing out an embroidery test pattern, they look for precise alignment of outlines and proper tension.

Walking Feet: Walking feet can be cleaned and oiled for smooth quiet motion. Bring the walking foot along to have it checked through!

What to bring with a machine for service? Machine, foot control, power cord, standard zig-zag presser foot (not a 1/4 inch foot), a standard zig-zag throat plate (not a straight stitch throat plate), bobbin case, and correct bobbin. If bringing an embroidery machine, also include an embroidery hoop and the embroidery foot.

A yearly service will prevent any heavily worn areas to be caught before they cause worse problems down the road. For example, if a shaft or barring is not properly aligned, the excess wear will eventually cause other areas of the machine to be prematurely worn out. Most machines do not need major replacement of parts when preventative maintenance is scheduled. Just like our bodies, teeth and car receive yearly check-ups, make sure your sewing machine receives equal treatment.

If it has been over a year (or five) since your last service, make arrangements now for its own special spa day. Otherwise, start saving now for your next sewing machine. You will need a new one before you know it!

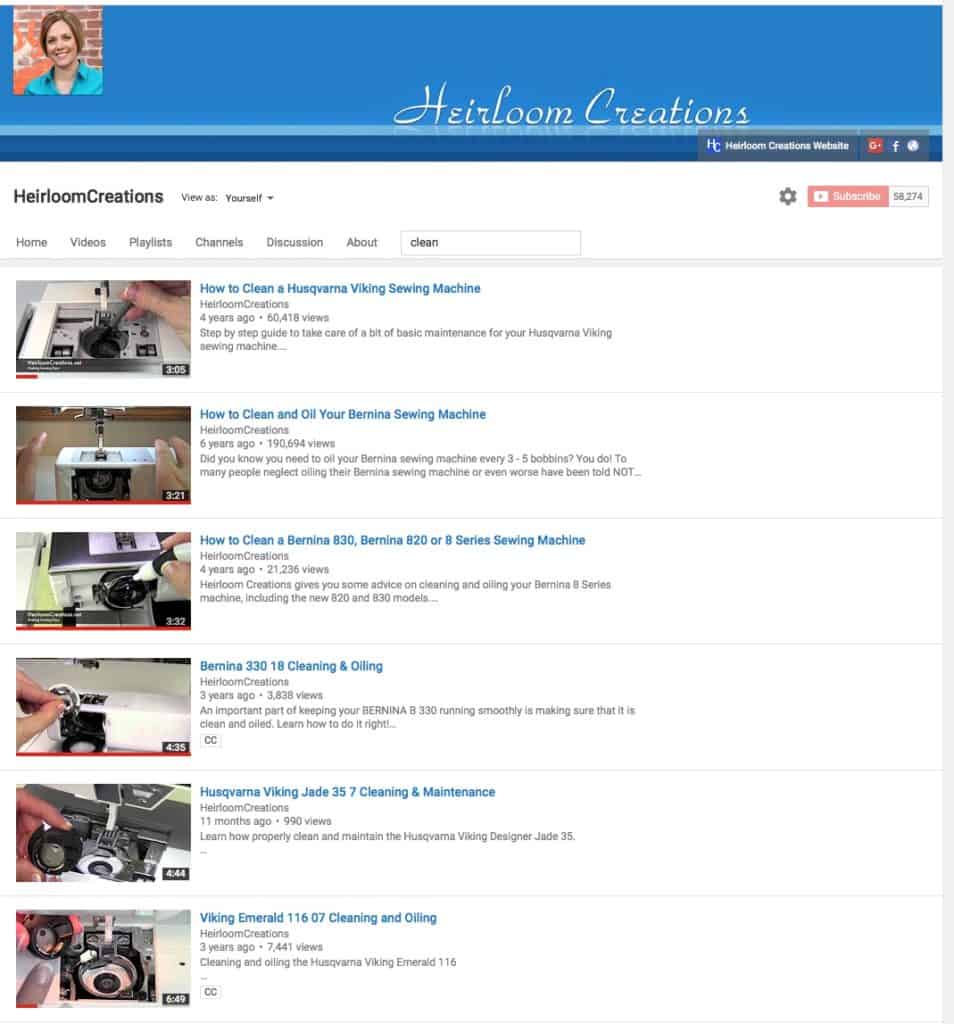

Here is a complete list of all our cleaning and oiling videos.